In today’s fast-paced manufacturing industry, finding the right custom aluminum die casting service is crucial for businesses looking to create high-quality, precision components.

This comprehensive guide will walk you through the process of selecting the perfect partner for your die casting needs. We will explore the key factors to consider, the benefits of custom Aluminum die Casting, and answer some frequently asked questions to help you make an informed decision.

Introduction

Custom aluminum die casting is a manufacturing process that involves creating intricate metal parts by injecting molten aluminum into a mold cavity. This method is known for its precision and repeatability, making it a preferred choice for industries like automotive, aerospace, electronics, and more. When it comes to choosing the right custom aluminum die casting service, the stakes are high. This guide will provide you with the knowledge you need to make an informed decision.

Understanding Custom Aluminum Die Casting

What is Custom Aluminum Die Casting?

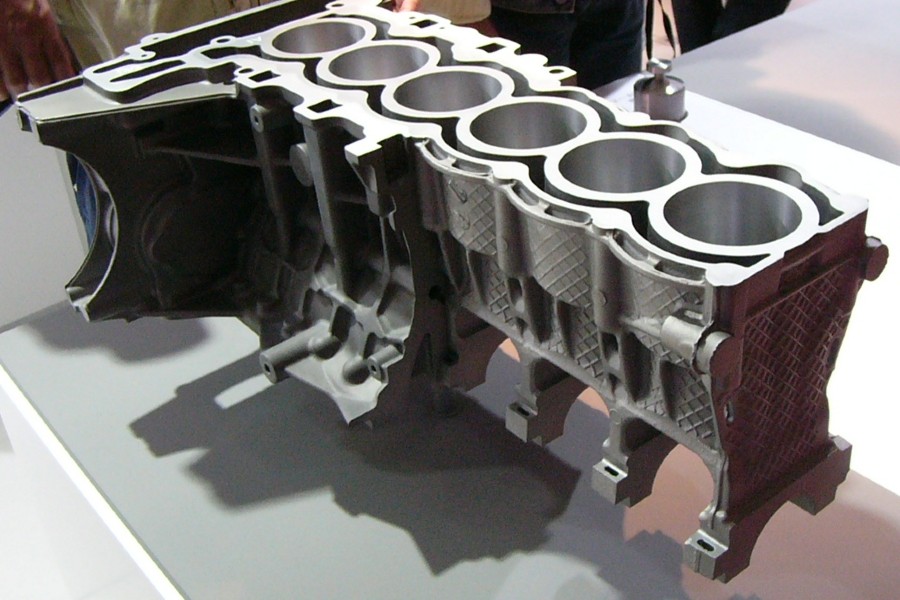

Custom Aluminum die Casting manufacturer is a manufacturing process that allows for the production of complex and dimensionally precise aluminum parts. The process starts with the creation of a mold, often made from steel or other durable materials. This mold is designed to the exact specifications of the desired part. Molten aluminum is then injected into the mold, where it solidifies and takes the shape of the mold cavity. Once the part has cooled and solidified, it is ejected from the mold, resulting in a high-quality aluminum component.

Advantages of Custom Aluminum Die Casting

There are several advantages to choosing custom aluminum die casting for your manufacturing needs:

- High Precision: Custom aluminum die casting allows for the production of parts with tight tolerances and intricate details.

- Cost-Effective: The process can be highly efficient for high-volume production runs.

- Material Flexibility: Aluminum is lightweight, corrosion-resistant, and can be easily recycled.

- Consistency: Die casting ensures consistent part quality and dimensional accuracy.

- Reduced Post-Processing: Parts often require minimal finishing work, saving time and money.

Choosing the Right Die Casting Service

Assessing Your Needs

Before you begin your search for a custom aluminum die casting service, it’s crucial to assess your specific needs. Consider the following:

- The complexity of your parts.

- The volume of parts required.

- Material specifications and requirements.

- Any special finishing or coating needs.

Understanding your requirements will help you narrow down your choices and find a service provider that can meet your expectations.

Quality and Precision

Quality and precision are paramount in the custom aluminum die casting process. Look for a service provider with a track record of producing high-quality, defect-free components. Consider their quality control processes and certifications to ensure consistent results.

Material Selection

Discuss your material requirements with potential service providers. Aluminum alloys come in various types, each with unique properties. The right material choice can significantly impact the performance and longevity of your parts.

The Importance of Experience

Experience matters in the world of custom aluminum die casting. Look for service providers with a proven track record in producing parts for your industry. An experienced partner will have the expertise to overcome challenges and deliver exceptional results.

Equipment and Technology

State of the Art Machinery

The equipment used by a custom aluminum die casting service plays a vital role in the quality of the parts produced. Choose a service provider with modern machinery and advanced technology to ensure efficiency and precision.

Quality Control

Quality control is critical to the manufacturing process. Inquire about a service provider’s quality control measures, including inspections, testing, and certifications. Reliable quality control leads to consistently high-quality parts.

Quality Assurance and Testing

Ask potential service providers about their quality assurance processes. Understanding how they ensure the quality and performance of your parts will give you peace of mind. Look for providers that offer testing and inspection services to identify any defects or irregularities.

Cost Considerations

Comparing Quotes

Obtaining quotes from multiple custom aluminum die casting service providers is a smart move. Compare these quotes carefully, but keep in mind that the lowest cost doesn’t always equate to the best value. Consider the overall quality, capabilities, and reputation of the provider.

Hidden Costs

Be aware of any potential hidden costs, such as tooling charges, setup fees, or additional finishing processes. Transparent communication with your service provider is essential to avoid surprises.

Lead Times and On-Time Delivery

Timely delivery is crucial to your manufacturing process. Inquire about lead times and the provider’s track record for on-time delivery. Delays can disrupt your production schedule, so choose a provider with a history of reliability.

Environmental Considerations

Sustainability in Die Casting

As environmental concerns become more significant, consider choosing a service provider with sustainable practices. Some die casting companies prioritize eco-friendly processes, such as recycling and reducing waste. Choosing an environmentally responsible partner can align with your company’s values and goals.

Customer Service and Communication

Effective communication is essential in any partnership. Look for a custom aluminum die casting service provider that values open and transparent communication. A responsive and collaborative partner can make your manufacturing process smoother and more efficient.

Case Studies

To gain a better understanding of a potential service provider’s capabilities, ask for case studies or references from their previous projects. Examining their past work and success stories can help you make an informed decision.

Why Custom Aluminum Die Casting Matters

Custom aluminum die casting matters because it provides a cost-effective and high-precision solution for manufacturing complex metal parts. The process ensures consistency, quality, and efficiency, making it an indispensable option for various industries.

Finishing Line

Selecting the perfect custom aluminum die casting service is a crucial decision for any manufacturing business. By considering your specific needs, evaluating the provider’s experience and capabilities, and keeping an eye on quality and cost factors, you can make an informed choice that will positively impact your production process.

- Mayor Adams Celebrates 100th Young Adult From Foster Care Secured Housing

- NYC Health Department Unveils 2023 Data On Rising Sexually Transmitted Infections

- Complete Beach Vacation Packing List: All You Need For An Ideal Trip

- Sposnored Love: Discover the Thrills of Yaaman Adventure Park in Jamaica

- Deep Cleaning Tips For Allergy-Proofing Your Home This Season

Become a Harlem Insider!

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact